3D Printing in Medicine: Revolutionizing the Medical Sector

- Aug 19, 2025

- 2 min read

Updated: Aug 25, 2025

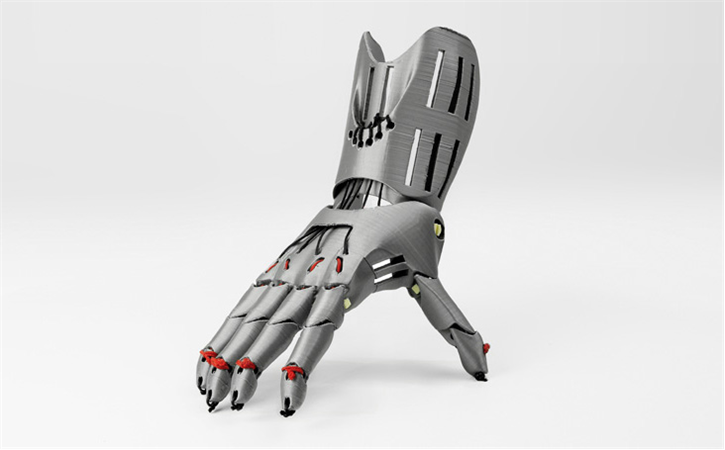

From prosthetic limbs to personalized implants, 3D printing technology is rapidly transforming the medical field. This innovative process offers a unique opportunity to create customized solutions for patients, pushing the boundaries of traditional healthcare practices.

The Impact of 3D Printing in Medicine

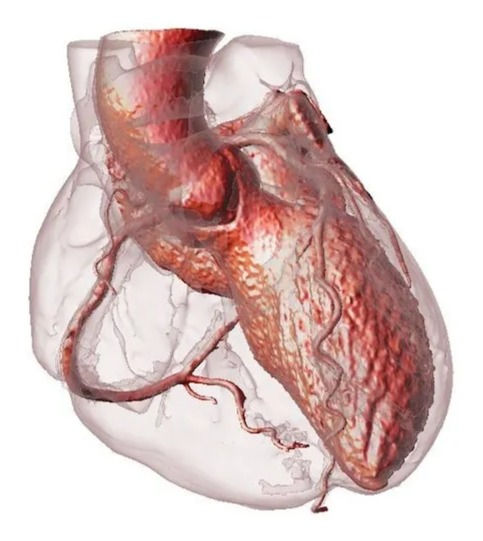

3D printing allows for the creation of patient-specific models of organs, bones, and other anatomical structures. These models are invaluable for surgeons, enabling them to:

Plan complex surgeries with greater precision. By studying a 3D-printed replica of a patient's organ, surgeons can identify potential problems and refine their surgical approach, leading to better outcomes and reduced complications.

Practice and rehearse procedures beforehand. Surgeons can use 3D-printed models to practice complex surgeries beforehand, improving their skills and confidence, ultimately leading to shorter surgery times and improved patient experiences.

Educate patients and their families. 3D-printed models can be used to show patients and their families what to expect during a surgery, leading to better understanding and informed decisions.

Beyond Surgical Planning

3D printing is also being used to create a range of innovative medical devices and implants, including:

Prosthetics: 3D-printed prosthetics are now available for patients of all ages, offering a more comfortable and functional solution than traditional prosthetics.

Implants: 3D printing allows for the creation of custom-made implants, such as hip and knee replacements, which can be perfectly matched to a patient's individual anatomy.

Medical devices: 3D-printed medical devices, such as splints and casts, can be quickly and easily created at the point of care, providing patients with customized solutions without the need for long waiting lists.

The Future of 3D Printing in Medicine

The potential of 3D printing in medicine is vast. Researchers are currently exploring the use of 3D printing for:

Bioprinting organs and tissues for transplantation: This technology could revolutionize organ transplantation, addressing the critical shortage of donor organs.

Creating personalized drug delivery systems: 3D-printed drugs could be designed to release medication at specific times and dosages, improving the efficacy of treatment.

Developing new medical devices and surgical techniques: 3D printing will continue to drive innovation in the medical field, leading to new and improved ways to diagnose and treat diseases.

As 3D printing technology continues to evolve, its impact on the medical sector is sure to become even more profound. This transformative technology has the potential to improve patient outcomes, reduce costs, and ultimately make healthcare more accessible and personalized.

Tempus 3D is an HP Certified 3D Printing service bureau located in British Columbia, Canada. Tempus offers 3D printing services using HP MJF technology, Sinterit SLS technology, and Formlabs 3D printing technology to offer Nylon PA 12S, TPU, and a wide variety of resins including clear resin in house. Tempus serves clients across Canada and the US, and has next day shipping to most locations in Western Canada and the Pacific Northwest including Vancouver, Calgary, Edmonton, Kelowna, Victoria, Spokane, Seattle, and Portland.