Why Choose Nylon PA12 White?

Nylon PA12 White offers the same mechanical strength, accuracy, and repeatability as standard PA12, with the added advantage of a bright, uniform white finish. This makes it especially well-suited for parts that require excellent detail, surface quality, and color compatibility for painting, dyeing, or post-processing.

It is widely trusted for both functional prototypes and low- to mid-volume production, balancing performance with cost efficiency.

3D printing technology

HP Multi Jet Fusion 5420W

Dimensional accuracy

+/- 0.3% with a lower limit of +/- 0.3 mm

Maximum build size

380 x 285 x 380 mm (14.9" x 11.2" x 14.9")

Designed for High-Quality, Versatile Parts

Strength and accuracy with a premium white finish.

Nylon PA12 White combines reliable mechanical performance with a smooth, high-contrast surface that enhances both aesthetics and functionality. Its properties make it an excellent choice for parts requiring tight tolerances, consistent durability, and visual appeal.

Industries rely on PA12 White for consumer goods, medical devices, automotive interiors, and functional prototypes where appearance and strength are equally important. The clean white base also makes it ideal for custom finishing, dyeing, Cerakote or branding applications.

Key Benefits

-

Strong and Versatile – Balanced mechanical properties for both prototypes and production parts.

-

Clean White Finish – Bright, uniform color that enhances aesthetics and allows easy painting, dyeing, or branding.

-

High Accuracy – Produces detailed, isotropic parts with consistent dimensional stability.

-

Durable and Reliable – Excellent resistance to impact, wear, and repeated use.

-

Cost-Efficient – Suitable for both functional prototyping and low- to mid-volume manufacturing.

-

Consistent Quality – Smooth surface finish ideal for post-processing and customization.

Applications

-

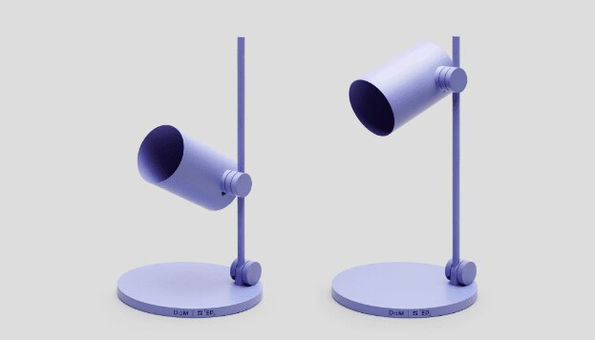

Consumer Products – Housings, enclosures, and components requiring a clean aesthetic.

-

Medical Devices – Functional prototypes and skin-safe end-use parts.

-

Automotive Interiors – Durable components with a high-quality finish.

-

Custom Finishing Projects – Parts designed for painting, coating, or dyeing.

-

Prototyping and Production – Reliable material for prototypes, jigs, fixtures, and small- to medium-batch runs.

-

Industrial Goods – Lightweight, accurate, and durable components for general use.

HP Multi Jet Fusion (MJF) delivers exceptional precision and surface quality for end-to-end production at low cost. Ideal for low- to mid-volume manufacturing, it’s trusted by global leaders including Volkswagen, BMW, and John Deere for producing durable, high-performance production-grade parts.

Technical Specifications

Accuracy

+/- 0.3% (minimum of +/- 0.3 mm)

Layer thickness

0.08 mm

Tensile breaking load

44 MPa

Modulus of elasticity

1600 MPa

Elongation at break

12%

Flexural modulus

1800 MPa

HDT 0.45 MPa

175º C

Izod impact resistance

3.5 kJ/m²

Data Sheets

Design Guidelines

Max build volume

380 x 284 x 380 mm (15 x 11.2 x 15")

Min wall thickness

0.6 mm (flexible), 2 mm (rigid)

Connecting parts

min 0.5 mm between part interface areas

Moving parts

min 0.7 mm between faces of printed assemblies

Emboss / deboss

min 0.5 mm

Design Considerations

-

Thin and long parts, as well as large flat surfaces, may be prone to warping. Consider PA12 Glass Bead as an alternative material for these parts.

-

Consider hollowing or adding internal lattice structure to large solid pieces to improve accuracy and minimize cost.

-

Hinges, sockets, and linked parts can be integrated into the design.

Finishes

.jpg)

Raw (white)

After the part has been printed it is ready for use, but has a powdery look and feel. Best suited for functional prototypes and non-visible parts.

Cerakote is a thin-film ceramic coating applied to 3D printed parts to improve looks and functionality. A variety of colors are available.

A chemical vapor is used to smooth the surface of the part. Vapor smoothing can also enhance material properties and brighten colors when dyeing.

.jpg)