Why Choose PLA?

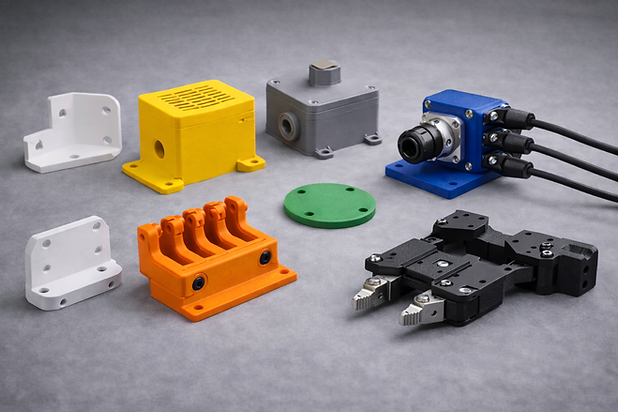

PLA is a widely used FDM thermoplastic ideal for concept models, form-and-fit testing, fixtures, housings, and non-load-bearing components where dimensional accuracy and visual quality are critical.

In controlled indoor environments, PLA can also be used for light-duty end-use parts, including covers, organizers, and consumer-facing components that do not require elevated temperature or high mechanical resistance.

3D printing technology

Maximum print size

256 × 256 × 256 mm (10.1" × 10.1" × 10.1")

PLA offers predictable print behavior and excellent surface resolution, supporting fast design iteration and reliable part reproduction. Its consistency makes it well suited for assembly verification, presentation models, light-duty fixtures, and short-run functional components.

PLA is commonly used throughout early and mid-stage development, allowing teams to validate geometry, ergonomics, and assembly before transitioning to higher-performance materials for load-bearing, high-temperature, or long-term service applications.

Key Benefits

-

Fast, cost-efficient production – Enables quick turnaround for development and internal use

-

High dimensional accuracy – Maintains reliable geometry for fit and assembly checks

-

Clean, consistent surface finish – Suitable for visual review and presentation

-

Predictable print performance – Supports repeatable results across multiple builds

Applications

-

Concept and presentation models – Visual parts for design reviews, client approvals, and demonstrations

-

Fit, form, and assembly validation – Checking clearances, interfaces, and part alignment

-

Light-duty fixtures and guides – Assembly aids and positioning tools for internal workflows

-

Test and evaluation components – Parts used during product development and refinement

Need a custom color or multi-color part? Contact our team or include details in your quote request to discuss available options.

Technical Specifications

Density

1.24 g/cm³

Tensile Strength

35 MPa (X–Y) | 31 MPa (Z)

5,076 psi (X–Y) | 4,496 psi (Z)

Tensile Modulus (Young’s Modulus)

2,580 MPa (X–Y) | 2,060 MPa (Z)

374 ksi (X–Y) | 299 ksi (Z)

Elongation at Break

12.2 % (X–Y) | 7.5 % (Z)

Flexural Strength

76 MPa (X–Y) | 59 MPa (Z)

11,023 psi (X–Y) | 8,557 psi (Z)

Flexural Modulus

2,750 MPa (X–Y) | 2,370 MPa (Z)

399 ksi (X–Y) | 344 ksi (Z)

Impact Strength (Notched Izod)

26.6 kJ/m² (X–Y) | 13.8 kJ/m² (Z)

Heat Deflection Temperature (HDT)

54 °C (129 °F) @ 1.8 MPa

57 °C (135 °F) @ 0.45 MPa

Vicat Softening Temperature

57 °C (135 °F)

Water Absorption (Saturated, 25 °C / 55% RH)

0.43 %

Note: Mechanical properties may vary depending on print orientation, processing parameters, and part geometry. Values are provided for design reference only.

Produce durable, cost-effective parts using Fused Deposition Modeling (FDM). Known for its versatility and broad material selection, FDM is well suited for functional prototypes, fixtures, and low-volume components where strength, speed, and efficiency matter.

Design Guidelines

Minimum wall thickness

≥ 1.0 mm

Unsupported overhangs

≤ 45° from horizontal

Bridge length

≤ 5 mm for best results

Clearance (moving parts)

≥ 0.5 mm

Load orientation

Design loads along the X–Y plane

*Recommendations vary based on geometry and application. For full details, see the full FDM design guide.

Note: Print orientation can affect part strength and performance. If your application requires a specific orientation, please include this in the quote notes or reach out to our design team for support.